MaCaW Project (Making Carbon Work)

University of Central Lancashire, Preston

Our Story

In the UK today, 20% of all carbon emissions are produced by SME’s. Often described as ‘hard to reach’, smaller businesses often don’t have the resources or connections to help arrest that figure. therefore here at the University of Central Lancashire (UCLAN), we decided to help change that.

The MaCaW Project (Making Carbon Work) is an EU EDRF Low-Carbon Project which helps support Lancashire based SMEs in reducing their carbon footprint. Based within a university, the project can tap into the wealth of knowledge and experience of leading academics.

Our project director, Professor Karl Williams is an academic and industry lead specialist in waste management. We also have access to academics with expertise on renewable energy and more efficient business practices/process.

The Challenge

The SMEs that we have engaged with are becoming increasingly more aware of their role and importance in our shared global interest of reducing CO2 emissions. This has allowed for high levels of success vs targets following our engagement. Also, general uptake of the project has been high with a healthy pipeline that has continued since our early stages of the project.

We have found working with Lancashire-wide business support networks such as BOOST incredibly helpful in spreading the word, especially in the early stages. We have also found success (pre-Covid) in leaflet dropping smaller, more traditional manufacturing businesses who are normally viewed as ‘harder to reach’.

The grant funding element of the project is obviously a big draw to for SMEs, especially those looking to make investments into low-carbon technology.

Our Solution

So far, we have worked with over 150 individual SMEs and have managed to save just under 1,5000 tonnes of CO2 emissions. We have also granted a total amount of £264 thousand through our grant funding programme that enables SMEs to make essential investments into reducing their carbon footprint.

The MaCaW Project worked with T&R Precision Engineering, a leading aerospace supplier on helping the business look towards low-carbon ways of working a new renewable energy. T&R Precision Engineering supplies CNC engineering tools to the industry to fit out aircraft such as Boeing and Airbus.

The company was keen to ensure that any growth in the company’s production and size was met by a commitment to reduce carbon emissions as much as possible. In total the company has reduced its carbon footprint by 60 tonnes a year, reducing its annual electricity bill by almost £20,000 thanks to the effort of the MaCaW Project.

MaCaW was also able to offer a grant to part fund the installation of large solar panels on the roof of the new factory. The solar PV system will cover the 6,000 square foot facility. With a £15,000 grant towards the total cost, the capital outlay for T&R Engineering was more manageable in the short term, with the system paying for itself in half the time. The system offsets 22.51 tonnes of carbon emissions per year.

FOR FURTHER INFORMATION CLICK HERE.

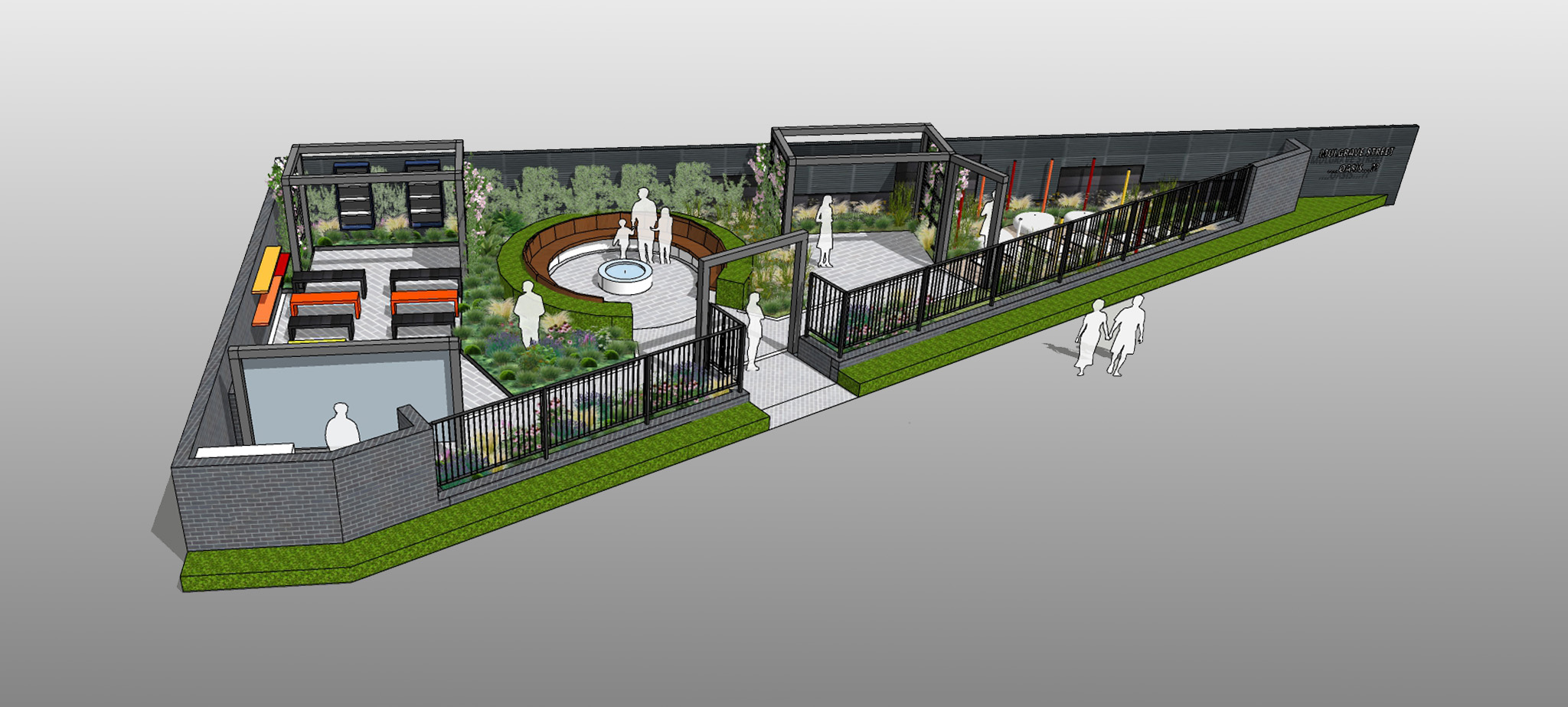

Peter Burn from MaCaW with Tim Maddison of T&R Precision Engineering

Peter Burn from MaCaW with Tim Maddison of T&R Precision Engineering

MaCaW Logo

MaCaW Logo