Whalley Community Hydro

Lancashire

Our Story

The initial idea for the Whalley Community Hydro plant was born out of a single idea and a group of enthusiasts to drive it forward. The Transition Towns movement back in 2008 was the idea of developing a smooth transition to a more sustainable, low carbon future. Specifically, reducing our carbon emissions and producing renewable energy. These enthusiasts were a varied group of retired men, with different background in skills, but shared a concern for the environment and future generations.

They identified the Whalley Weir as an ideal site for the project, given its established water pipe network and it’s ability to power an Archimedean screw turbine that produces up to 100kW of electric power.

Given the concept was still in it’s infancy, the project needed £750,000 to get it off the ground and drive it forward, this came from just over 300 incredibly generous people, most of whom came from East Lancashire. this gave us the final push to get the project over the line and we were able to see our initial idea from 2008 come to fruition five years later.

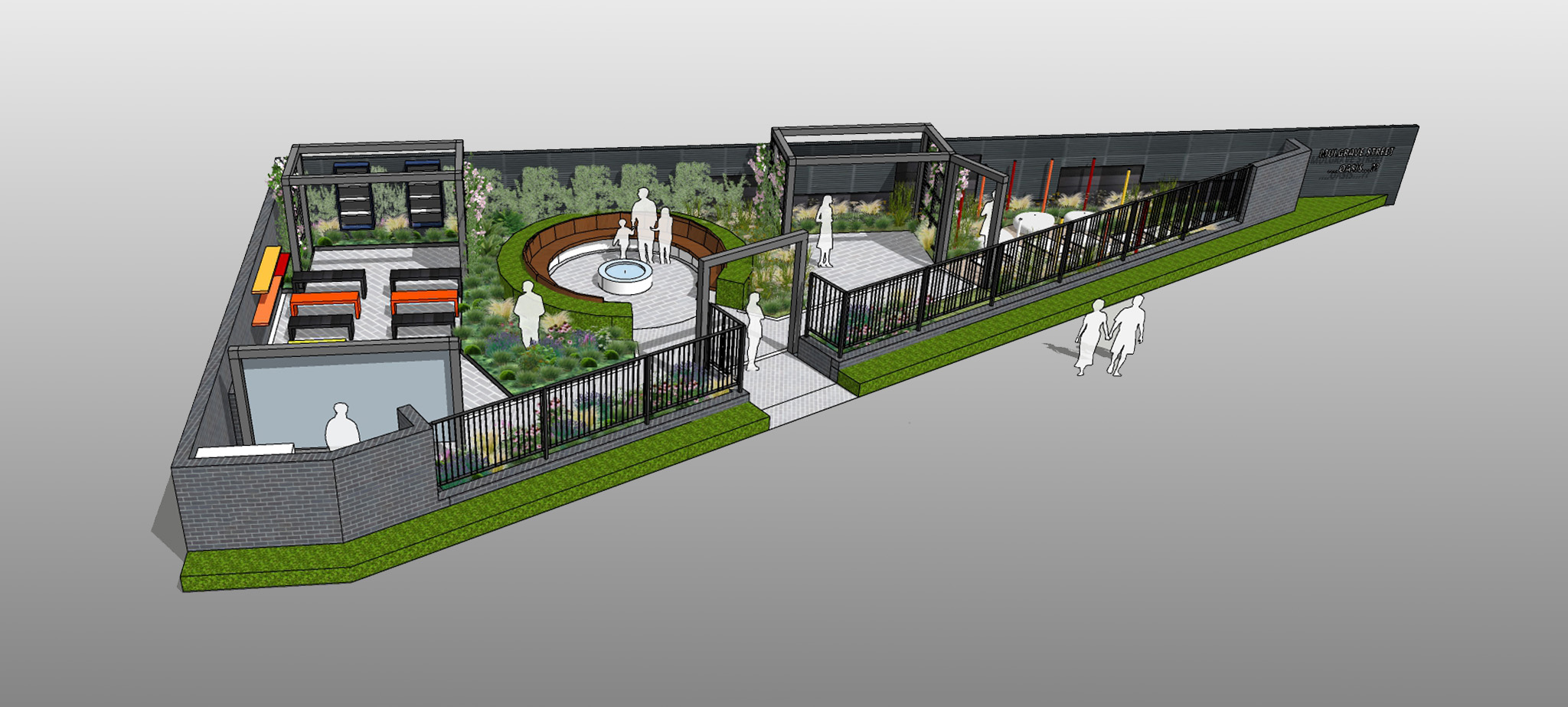

We now have a fully sustainably powered 100kW hydro installation at Whalley Weir, providing water to an area of 315 sq km’s of built up and rural areas, donating a fifth of the income it receives for Community Benefit to fund further carbon reduction and renewable energy schemes.

The Challenge

A project team with a range of skills, enthusiasm, and stamina was crucial in being able to engage with commercial firms, local authorities, and statutory bodies, like the Environment Agency. Effective management of our team allowed us to effectively develop the business plan, as well applying for grant applications and keeping track of finances.

In the project’s infancy, we visited a lot of other schemes who were often frank about where they went wrong and what they would do differently. We knew that to get our planning application granted, extensive research into river flows and effective lobbying was required, and took a considerable amount of time and resources to ensure the application was successful.

A low lead hydro generation scheme involves regular electrical and mechanical servicing of the plant, requiring constant attention to keep debris screens clear. This presented a big challenge for us given the size of our plant and would recommend mechanical means be considered for inclusion at the design stage; retrofitting can be problematic and expensive.

We were lucky in the fact that we benefit from a good level of feed-in tariff (FIT). Each hydro scheme is in a unique river location and there are high civil mechanical and electrical engineering costs. A steep reduction in FIT has been near fatal for the sector, with new projects unlikely to be financially viable unless the electricity generated can be used on site rather than sold off to the grid.

Our Solution

The large catchment area of the river Calder includes access to a large area of land so the river often brings with it quantities of vegetation and urban detritus, especially in Autumn and Winter when we hope for peak output. This allows to quickly block the screen and reduce power, so the plant remains at near optimal output by a seven-strong team of volunteers who crucially attend the plant when required. By giving up their time, they help minimalise operating costs.

The river also benefits from a ‘high base flow’, which ensures a dependable supply of water and thus a good level of output from the plant. The electricity generated is the fed into the nation grid and sold off to a company that buys 100% renewable energy. We also benefit from the Government’s Feed-in Tariff, further supporting income.

In 2020, we established a Community Benefit Fund to support local sustainable development and carbon saving projects that tackle climate change, promote energy efficiency and reduce fuel poverty. This is funded through revenue from the sale of electricity generated from the plant, which has always focused on being a Community Benefit Society. In the first five years, the fund has distributed over £75,000 to around 13 carbon saving schemes.

FOR FURTHER INFORMATION CLICK HERE.